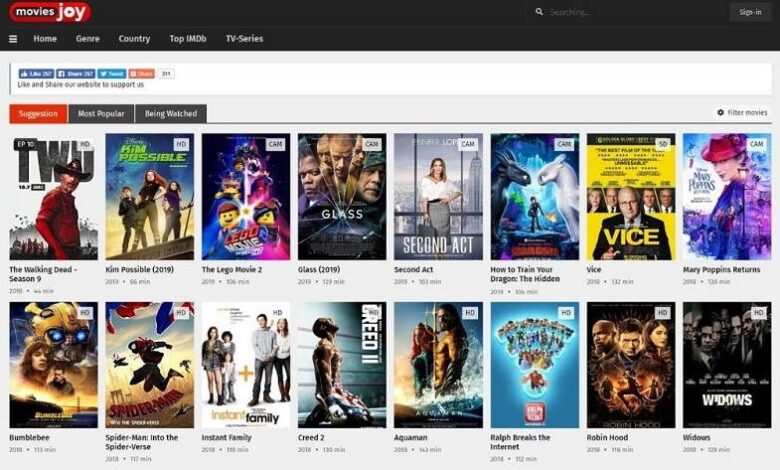

Moviesjoy is a free streaming platform. Users can watch their favorite shows and Movies for free without having to register. This website has a fantastic design. So, in the centre of the homepage, there’s a big, wide search bar where you can find for films. In addition, the user can see a menu that contains all of the streaming categories.

The Moviesjoy , like other popular streaming websites, has a huge library of films and TV shows. It presently has over 10,000 films and TV shows in its library. As a result, you’ll be able to find all of your favourite movies. The videos on the list are labelled as either HD or CAM. Moviesjoy will find you in locating the highest-quality version of each movie. As a result, you can download and watch a video at a later time. To download a video, we strongly advise you to use a VPN. As a result, another benefit of Moviesjoy is that it requires fewer advertisements.

As a result, watching movies on this platform is both enjoyable and entertaining. Moviesjoy, on the other hand, isn’t just a website that lets you watch videos for free. The vast majority of other sites offer the same website, but not all of them are legit.

How to Safely Visit Websites for Online Movie Streaming?

Many free movie streaming sites are infected with malware or malicious software. As a result, if it is downloaded, it will have a negative impact on the computer. The government has also penalized sites like Moviesjoy to for hosting copyrighted content. Users will never admit whether or not their favourite work is copyright. As a result, if people are caught watching non-copyrighted information, it may result in difficulties and a violation of the country’s legal system.

MoviesJoy Alternatives to Watch Free Movies

This article will provide a list of some of the best websites to use as an alternative, such as Moviesjoy.

1. YesMovies

Yesmovies is a good alternative to moviesjoy for watching full HD free online movies. You may watch the most recent episode series, as well as over 9000 free streaming movies, documentaries, and TV episodes, on the internet. You may also watch movies without needing to register on this website. You may watch free streaming movies by just clicking the start button.

2. FMovies

This is another great website that allows you to stream movies and TV shows in high definition video quality for free and without any limits. On best moviesjoy alternative website, FMovies offers users to search for movies or TV shows based on criteria like as most viewed, genres, country, year, and so on. The website offers a diverse selection of movies in categories such as Action, Adventure, Biography, Thriller, Romance, and others.

3. Putlocker

Putlocker is a free online movie streaming website. The biggest benefit of this service is that you may watch movies and TV shows without having to create an account. This is the best moviesjoy alternative website. The content is also available in high-definition format for download. On Putlocker, everyone will find something to their liking. A user can look for and watch movies in a variety of genres, including drama, comedy, crime, mystery, thriller, and others. A big library of Chinese films is available on the site. Without a doubt, it is one of the best and most popular free movie streaming sites available. The user interface is really simple and easy to use. You should give it a shot.

4. PrimeWire

Although the site’s annoying advertisements made us think twice about adding it to our list, Primewire‘s extensive library and simple interface convinced us to do so. Another benefit of this site is that it displays all of the relevant information with a cursor point, such as the IMDB rating, year, narrative, and genre.

5. Vudu

Vudu is a free online movie portal that may be accessed using a smartphone device. They offer applications for Android, iOS, PlayStation, Xbox, and the web. Surprisingly, they offer the highest videos for kids. I feel this is a reliable service if you’re bored at home and want to spend some time watching movies. They’re also divided into genres, with titles like comedy, romance, crime, suspense, action, horror, and family, among others.

6. 123Movies

As said in this article, 123Movies is one of the most popular movie websites. On this website, you can find Marvel movies and series in a variety of video codecs, including 4K, 1080p, 720p, and more. Watch movies online free full movie There is no need to register, and there is little to no advertising or popups on the best moviesjoy alternative website.

The new 123 Movies website’s home page is quite clear. You can watch all of the most recent movies and TV episodes on the 123Movie website. They’ve stated flatly that they don’t host movies, TV episodes, or series on their own server. This website’s content is derived entirely from other popular streaming platforms.

7. SolarMovie

Solar Movie is another site where you may watch movies and TV shows online from the comfort of your own home. There are no commercials on the website; but, until you connect to the viewing network, you may be exposed to advertisements from time to time. Without opening an account or paying a charge, you may watch all movies and television shows on the best miviesjoy alternative website.

On your PC or mobile device, you may watch over 10,000 shows and videos, as well as a range of video services. The platform contains no media files and instead acts as a registry. Solar Movies is the finest website to use if you want to watch Hollywood and Bollywood movies online without having to download anything.

8. Gostream

Gostream is a free online movie streaming site with a simple design that allows users to navigate it easily. If you already know what movie you want to see, simply type the title inside the search box on the top movies joy net alternative website. If you’re still looking for something else to watch, look through its collections. When you go to a movie’s page, you’ll see a lot of information about it, along with a video trailer and a rating.

9. IOMovies

IOMovies is increasing in popularity as a result of its vast collection and convenience of use, which does not require users to register or create an account. They not only distribute Hollywood movies and tv shows in India, but also Bollywood films. So, if you’re a big lover of Indian films, you’ve arrived to the right place. You may watch TV shows or movies based on their ratings, cast, and release year best moviejoy alternative website.

You won’t have to worry about having a horrible movie-watching experience because all of the content is available in high-quality versions. They’re also divided into categories to make searching and maintaining them easier. Another intriguing feature of this website is the user suggestion or recommendation section, which allows users to recommend a movie or TV show that isn’t already in their library. This is one of the most efficient ways for them to add collections and update their content.

10. LookMovie

Another amazing movie streaming site to watch out is LookMovie. The good news is that when watching a movie, you won’t be bothered by annoying ads or popups. Another advantage of visiting this website is that you will be able to watch high-quality video content. The appealing layout of this site, together with filters and other choices, makes it easy to find videos quickly.

11. M4UFree

M4Ufree extensive video library is primarily aimed to give free streaming of movies, short videos, documentaries, anime media, and other media. Make yourself at rest and watch free streaming movies and TV episodes on our website, which has no commercials or pop-ups, which is without a doubt its best feature.

This website offers a very consumer interface that makes it simple to find information you want to watch. This website does not require you to register or sign up in order to use it, so you may start streaming right away after exploring it. Furthermore, everything on this website is organised into categories like action, drama, comedy, horror, and humour, making it easy to find what you’re looking for.

12. Afdah

Afdah is a popular website for streaming movies and tv shows. It has an easy-to-use layout that is tidy and well-organized for all visitors. And, of course, their website does not contain adverts that direct you to other sites that provide alternatives to Windows Best Movies Joy.

Its unique feature is that their portal allows you to search for movies by language, year, genre, and country, with support for over 20 nations. Afdah’s streaming is definitely quick, and the majority of the movies and TV episodes offered on their sites are in HD. Surprisingly, the films are included on Afdah’s website. The film’s release date, language, and IMDB rating are among the info supplied. Before you watch a film, you can watch a trailer and read reviews about it.

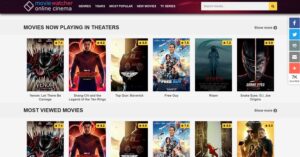

13. Movie Watcher

Movie Watcher offers a wide number of Hollywood movies and streaming shows to stream or download. Featured titles include most-watched movies, new releases, and films now showing in theatres. The IMDb rating and available print quality are shown in the thumbnails for each movie. By title, release year, or genre, a user can filter and search for his or her favourite movies or TV shows. The website also gives plot, directors, actors, country, and duration of the movie or TV show, in addition to general details. Overall, it’s one of the Best Free Movie Streaming Websites, with everything you need.

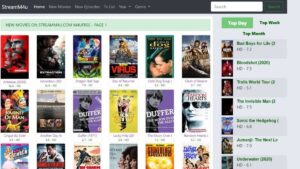

14. StreamM4u

Another free online movie site, StreamM4u, allows you to watch full movies and TV episodes without having to register. It works with both the brave browser and an adblocker. If you do not use an adblocker, I do not advise using this movie website. It has a good collection of TV shows and movies, and also information on genre, director, quality, and other factors. There is no IMDB rating or trailer link, however. It provides an adequate number of options for you to select a film of your choice greatest movies joy to alternative website.

The best part is that it gives you access to four or more streaming server options. If one player is unable to watch a movie, you can switch to another with a simple click. You may watch movies from the pasts for free right here. The quality of the video (HD, CAM, HDRip, HDTS, and so on) varies. The watching window does not have subtitles or video quality. You can only watch movies in full screen mode using it. In a word, it is not the best platform for watching movies online; rather, it is an option if the best movie streaming sites stated above are unavailable at your location.

15. Soap2Day

Soap2day, like Moviesjoy, is one of the top streaming websites. This allows you to watch movies and TV shows for free. This is a clean and decent interface that will make website navigation much simpler. Users can find films in a variety of genres, such as horror, action, adventure, drama, and so on.

This will also arrange movies by release date, IMDb rating, and other factors. This blog has a list of all of the top and well movies on the right sidebar. As a result, the customer can observe how the year of release makes the job easier. Furthermore, there is no federal law requiring in order to watch these movies.

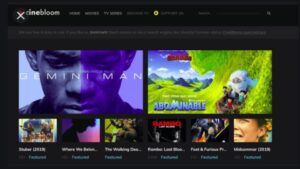

16. Cinebloom

Cinebloom, like Moviesjoy, is a popular and free online streaming platform. There are many movie collections, TV movies, and TV shows to choose from. As a result, on the homepage, you’ll find a few of the most recent releases. Cinebloom provides you with a range of options from many categories. Filtering the films and their release year can also be added. You can look for a specific movie using the search bar. Customers no longer need to register or sign up, as they do on the other sites on the list.

17. Movie4U

Film, romance, mystery, horror, comedy, biography, fantasy, and other sorts of action are all available on Movies4u. It includes a well-categorized movie portion. The database includes both old and new movies now showing in cinemas. You have free freedom to do whatever you choose. You can watch it on the web, or you can download it and watch it later. Movies4u is an amazing alternative to Moviesjoy sites for all your streaming requirements.

18. GoMovies

With GoMovies, you can watch movies for free online. Any videos stored in the firm’s archive can now be viewed. This website is really user-friendly. You’ll find movies categorized in a variety of genres here, and you may choose which one you wish to watch. You can also choose movies based on a country’s name. This website has all the capacity to keep you entertained, and you should try it instead of Putlocker, but the advertisements and displays on the site may irritate you.

19. PubFilm

The Pubfilm was one of the first and most popular streaming sites. As a result, it has one of the most extensive databases of films and television shows of all genres. And whether you’re looking for ancient classics or recent releases, you’ll find them all right here. The user can choose movies and TV shows based on popularity, genres, release year, freshly added, and other factors. So, once you’ve chosen a movie, the movie page will appear. Now you can see everything about the movie, including its genre, cast, director, and more. Users do not need to register in order to watch movies. As a result, choose a server to watch the video on and start watching.

20. LosMovies

LosMovies.com is a website where you may watch films for free. You can watch movies with English subtitles or in any other language you want. Los Movies will provide you with a list of currently showing theatrical films. When compared to other pages, this site’s activity is a little different. If you decide whatever movie you must watch, it will transport you to its secondary page, where you can select numerous server options for streaming the video. Now that it has a vast movie database, you might see it as a great alternative to Moviesjoy.

Check Over Other Articles Like

- Best SeeHD Alternatives

- Best TVMuse Alternatives Sites

- Kuttymovies 2021

- Best Project Free TV Alternatives

- Best Sites like LetMeWatchThis

Conclusion

Moviesjoy is a one-of-a-kind movie streaming website. You can watch your favourite movies and TV shows for free. It is not, however, the only feasible alternative. It makes absolutely no difference whether platform you utilise. Always use a decent VPN service and an ad blocker for added security. Then, similar to Moviesjoy.com, we compiled a list of ten of the best free streaming sites that you may use like Moviesjoy.